The Difference Between Hot Air Nonwoven Fabric and Spunbond Nonwoven Fabric in Diapers

2023-07-05 22:00

Diapers play a crucial role in ensuring the comfort and dryness of babies. The surface layer of a diaper is typically made of nonwoven fabric, which acts as a moisture-absorbing and soft barrier between the baby's skin and the absorbent core. Two commonly used types of nonwoven fabrics in diaper production are hot air nonwoven fabric and spunbond nonwoven fabric. This article aims to highlight the differences between these two materials, exploring their manufacturing processes and performance characteristics.

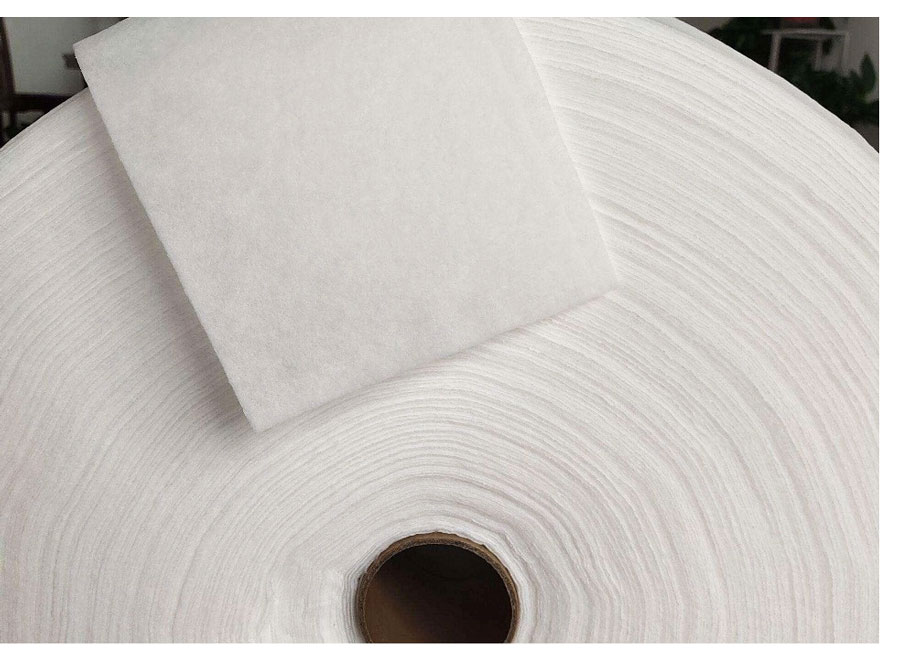

Hot Air Nonwoven Fabric:

Hot air nonwoven fabric, also known as thermal bonded nonwoven fabric, is produced by passing heated air through a fibrous web. The fibers in the web are thermally activated and bonded together, creating a durable and stable fabric. Hot air nonwoven fabric offers several advantages for diaper applications. Firstly, it provides excellent liquid permeability, allowing urine to pass through and be absorbed by the core efficiently. Secondly, it offers a soft and smooth surface, minimizing friction and reducing the risk of diaper rash. Additionally, hot air nonwoven fabric exhibits good breathability, enhancing air circulation and reducing heat build-up.

Spunbond Nonwoven Fabric:

Spunbond nonwoven fabric is manufactured by extruding continuous filaments of thermoplastic polymers, such as polypropylene, onto a conveyor belt. The filaments are then cooled, stretched, and bonded together to form a nonwoven fabric. Spunbond nonwoven fabric is widely used in diapers due to its unique characteristics. It offers high strength and durability, ensuring the diaper's structural integrity during use. The fabric has excellent liquid repellency, preventing any leakage from the absorbent core. Moreover, spunbond nonwoven fabric provides a smooth and silky surface, enhancing the comfort of the baby.

Differences:

Differences:

The primary difference between hot air nonwoven fabric and spunbond nonwoven fabric lies in their manufacturing processes. Hot air nonwoven fabric is bonded through thermal activation, while spunbond nonwoven fabric is created by filament extrusion and bonding. This variance in production techniques leads to differences in performance characteristics. Hot air nonwoven fabric excels in liquid permeability, breathability, and softness. On the other hand, spunbond nonwoven fabric offers superior strength, liquid repellency, and smoothness.

Both hot air nonwoven fabric and spunbond nonwoven fabric are widely utilized in diaper manufacturing, each offering distinct advantages. By understanding the differences between these two materials, the buyer can know the efforts made in developing diapers that prioritize comfort, dryness, and overall well-being for babies.

Get the latest price? We'll respond as soon as possible(within 12 hours)